Metal parts go through a wash to get rid of dirt and any impurities that remain after the production process. The parts are then dried using Nitrogen to keep moisture from forming and corroding the metal. This is a necessary process to ensure functionality of the part and provide a longer use. One of the outstanding properties of Nitrogen is a dew point ranging from -40 to -100F which provides a completely moisture-free environment.

Heat treating of metals and other materials consist of a wide range of different techniques to manipulate the molecular structure of the material. In cases that decarbonization of the material does not factor into the process, Nitrogen can be used as the controlled atmosphere.

This eliminates the ability for the material to react with any Oxygen and other residual molecules, preventing scaling. A Nitrogen Generator is effective at producing high purity N2

gas on demand using a simple and reliable process. The use of a Nitrogen Generator in heat treatment of metals streamlines the process, making it more safe, reliable, and cost-effective.

The inert properties of Nitrogen makes it widely used in the oil and gas industry. Nitrogen is odourless, non-polluting and non-reactive in nature – and that makes it highly suitable for e.g. pipeline inerting and oil well stimulation. It is also excellent for offshore and refinery processes.

During the refining process of crude oil into a variety petroleum based products, Nitrogen is injected into the system to help maintain the stability of the chemical reaction. Remaining hydrocarbons can lead to a potential explosion during operation.

Safety is a top priority in the oil and gas industry. Nitrogen ensures safety during e.g. tank cleaning operations and other situations where an inert atmosphere is needed.

Nitrogen gas plays an essential role in the pharmaceutical industry, with a broad range of applications ranging from packaging to fire suppression in an obviously volatile manufacturing environment. With recent technological advancements, on-site Nitrogen generation equipment can now provide purity levels equal to that of liquid Nitrogen, helping pharmaceutical manufacturers lower costs without sacrificing quality or efficiency.

As biofuel production becomes more and more widespread, the issue of safety, especially in terms of the handling, transporting, and storage of methanol - becomes more of a concern for experts to consider.

When methanol is stored in tanks, it has a tendency to form vapors that are extremely flammable. In an effort to prevent the formation of these vapors, Nitrogen gas is introduced as an inert gas to take up the extra space in the tank.

The process of using Nitrogen in atmosphere blanketing, or tank blanketing, for methanol gas increases the safety factor of storage and transport. Nitrogen is a clean, dry, inert gas that is nonflammable and noncombustible. Nitrogen is introduced to the tank to eliminate the presence of Oxygen, an essential factor for combustion.

The presence of Nitrogen in methanol, biodiesel, and soybean oil storage tanks also reduces Oxidation and other factors that affect the quality of the biofuel. So the process of Nitrogen blanketing not only increases the safety factor of storing and transporting biofuel, it also provides a high quality product.

Further contributing to the safety factor is the use of a Nitrogen Generator for providing high purity Nitrogen gas on demand for the tank blanketing process. A Nitrogen Generator eliminates the need for dealing with high pressure N2 cylinders while safely and reliably providing the purity and flow necessary to maintain the proper inert atmosphere for blanketing applications.

Nitrogen is widely used to provide blanket covering thus avoiding any explosions during chemical processing and storage. Further Nitrogen also prevents oxidation of reactive chemicals & petrochemicals. Exposure to Oxygen decreases chemical stability and alters the chemical's flavor, aroma, color, flammability, and storage life.

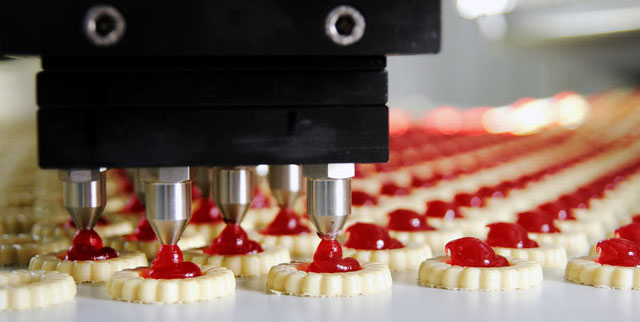

Nitrogen gas is widely used in food Packaging in order to preserve freshness, taste, texture, and flavor for longer periods of time. By creating a storage atmosphere that carefully controls the Oxygen and humidity levels,food products can remain fresh and crisp much longer, because the ripening process will be significantly slowed. Our PSA Nitrogen Generators are used to produce Nitrogen which is filled in a wide variety of food products (Potato Chips and other variants ). The inert gas when filled in a pack allows it to retain its contents in original fresh condition by avoiding its contact with air/moisture.

For this food manufacturers use Nitrogen flushing in sealing machines to force the regular air out of the packaging and inject Nitrogen gas into the packaging. Nitrogen doesn't react with food like Oxygen does, so foods stay fresher longer and it doesn't affect the flavour or texture of the food. And since the Nitrogen fills up the bag, it provides cushion and helps protect the delicate foods inside.

The use of Nitrogen to maintain an inert atmosphere above a liquid or powdered product inside a storage tank, silo, reactor, process equipment or other vessel. The inert gas will help prevent product degradation from moisture and Oxygen, control volatile emissions and safeguard against fires and explosions.

The use of Nitrogen to transfer liquid or powder products to and from railcars, tanker trucks, or storage vessels without requiring pumps, mechanical compressors or external power sources. Dry, inert Nitrogen is ideal for transferring toxic fluids, highly viscous fluids, ethical pharmaceuticals, flammable products, and materials which become corrosive when contacted with moisture.

The use of Nitrogen gas to displace air, flammable vapors, and contaminants from storage tanks, pipelines, process equipment, railcars, ocean bound containers, or other vessels.

Nitrogen gas is used to inflate the tires of racing cars, airplane tires and a few passenger car. Inflating tires with Nitrogen has many benefits like reduced tire temperature, maintenance of air pressure in the tires and increased tire lifespan. The comparatively bigger size of Nitrogen gas molecules doesn't seep out of tires as quickly as air does and thus helps in maintaining the pressure of the tires.